Our Facilities

Where Tropical Excellence Is Perfected, Packed, and Delivered.

Beaker Farms operates a fully integrated post-harvest and processing system designed to deliver consistent, premium-quality tropical fruit products to customers around the world. By managing ripening, processing, and packing in-house, we maintain strict quality control at every stage of the supply chain — from the moment fruit leaves the farm to the moment it is shipped out of Ghana.

This infrastructure allows us to minimize post-harvest losses, optimize food safety standards, guarantee reliable delivery timelines, and supply multiple product categories using the same carefully managed handling system.

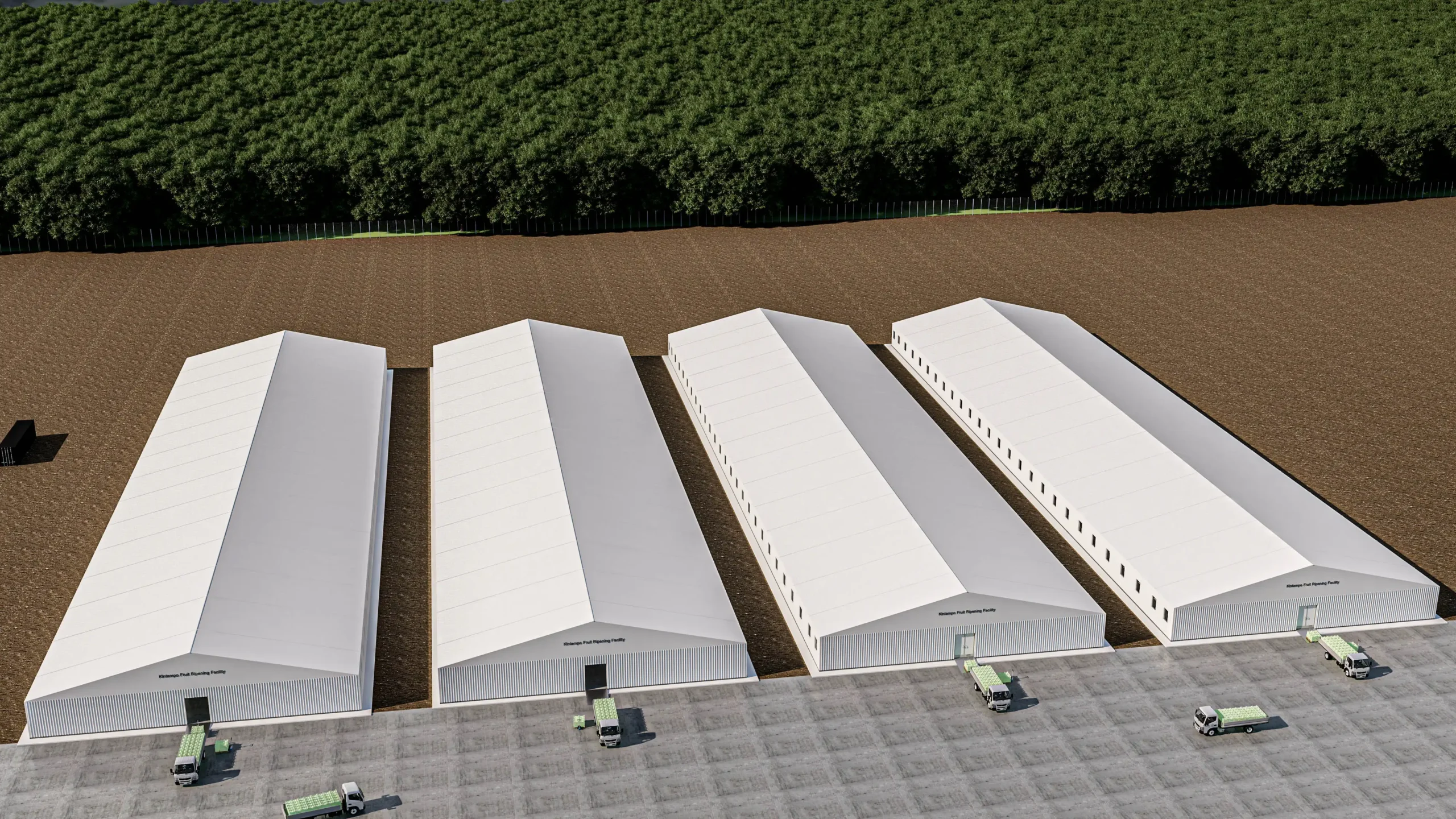

Our two primary facilities — the Kintampo Ripening Facility and the Kumasi Tropical Fruit Processing Facility — work together to ensure that every mango and pineapple meets international export and manufacturing standards.

Beaker Farms’ ripening facility is located in Kintampo, at the centre of Ghana’s main fruit-growing corridor. This strategic location ensures a short transport distance from farms to our site, reducing mechanical damage, lowering post-harvest losses, and preserving natural fruit quality.

Once mangoes and pineapples arrive at the facility, they undergo a carefully controlled post-harvest workflow:

Inside the ripening centre, we use ethylene-assisted natural ripening, which allows Beaker Farms to bring fruits to precise maturity levels depending on customer requirements. This gives us the flexibility to supply:

- Fresh export mangoes with controlled sweetness and firmness

- Ripe fruits for ready-to-eat products

- Fully matured fruits for purée and frozen fruit production

Ripening is carried out on palletized systems to ensure minimal handling and uniform airflow, helping every fruit achieve consistent color, flavor, and Brix levels.

Beyond product quality, the ripening facility supports local economic development. The site provides employment for youth in surrounding communities, skill development in modern fruit handling, and long-term career opportunities in Ghana’s agribusiness sector. As demand grows, the facility has been designed to scale, allowing Beaker Farms to increase ripening capacity and adopt additional automation tools.

After ripening, fruits are transported to our modern processing facility in Kumasi — the operational centre of Beaker Farms’ value-added production. Here, fruits are graded, peeled, diced, crushed, or packaged depending on their final destination.

The Kumasi facility is responsible for the company’s four major product categories:

Export-grade mangoes and pineapples are carefully handled to maintain firmness, sweetness, bright color, and long shelf life during overseas transport. Fruits are packed in ventilated export cartons under strict cold- chain control and shipped to Europe, North America, and the Middle East.

Our controlled-atmosphere ripening rooms and pre-cooling facilities ensure uniform fruit maturity and extended shelf life—serving both local and export clients.

Food Safety & Quality Assurance

Food safety is a core part of our operations. Both facilities follow:

- International hygiene and sanitation procedures

- Traceability across every lot and load

- Cold-chain handling from ripening through shipping

- Strict inspections at receiving, processing, and packing stages

This ensures all Beaker Farms products meet the expectations of premium international buyers.

Why Our Facilities Matter

- Consistent product quality year-round

- Lower post-harvest losses and improved pricing

- Reliability for international buyers

- Cleaner, safer, traceable food handling

- Ability to scale capacity as demand grows